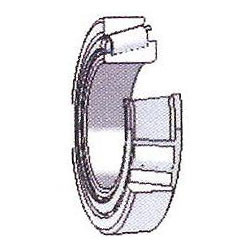

Taper Roller Bearings

Price 500 INR/ Bottle

Taper Roller Bearings Specification

- Cage Material

- Steel

- Precision Rating

- P0, P6, P5, P4

- Retainer

- Steel

- Lubrication Type

- Other

- Inside Diameter

- 24 mm - 380 mm

- Thickness

- 15 mm - 42 mm

- Bearing Type

- Taper Roller Bearing

- Material

- Chrome steel

- Structure

- Taper Roller

- Seals Type

- Open

- Number Of Rows

- Single or Double

- Bore Size

- 24 mm - 380 mm

- Outside Diameter

- 52 mm - 540 mm

- Limiting Speed

- 2400-9000 RPM

- Load Capacity

- High

- Feature

- Low noise, High durability, Easy to install

- Application

- Automotive, Industry Machinery, Gearboxes, Axles, etc.

- Standard

- ISO

- Dynamic Load Rating

- As per bearing series

- Static Load Rating

- As per bearing series

- Finish

- Polished

- Temperature Range

- -30°C to +120°C

- Hardness

- 58-62 HRC

Taper Roller Bearings Trade Information

- Minimum Order Quantity

- 100 Bottles

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 500 Bottles Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- West India

About Taper Roller Bearings

Our clients can avail a superb of Taper Roller Bearings from us. We give our superior quality polish to our bearings that enhance their durability and corrosion resistance nature. Offered bearings are used in automotive products, precision machinery, parts and mainly used in rotating shafts and in housings. Due to their sturdy construction, these bearings enable them to carry heavy weights and let them manage both radial and axial loads. Further, these Taper Roller Bearings are checked on various quality parameters to ensure their excellent strength.

Features:

- Accurate dimension

- Heat resistance

- Precisely designed

Product details

| Condition | New |

| Shape | Round |

| Material | Stainless Steel |

| Color | Silver |

| Bearing Number | 32210 J2/Q |

Specification:

| DELUX Part No. | Equivalent No. | Vehicle Model |

| 09067/09195 | M 12644/611 | MF 1035, Standard 20 |

| 11590/11520 | | M&MJEEP |

| 1988/22 | | TATA 207 / SIERRA / ESTATE, FARMTRAC, B-275/270/444/434, SWARAJ 735/720 |

| 30203 | | DCM TOYOTA |

| 30204 | | MARUTI VAN, STD 20, DCM TOYOTA, TATA 1612, BEDFORD J-4 & J-6 |

| 30205 | | TATA 206/207, SIERRA, ESTATE, SUMO, TEMPO TRAVELLER, |

| | | ESCORT 335/345/3000-3600, HWD 15, SUZUK! 1000, SWARAJ 720 |

| 30207 | | AMBASSADOR / SWARAJ MAZDA / ESCORT 355 & 345 TRAC. / |

| | | NISAN JONGA / KIRLOSKAR / D-40064 TRAC |

| 30208 | | TATA 207, SIERRA, ESTATE, 407 |

| 30209 | | TATA 207, HWD 35, SWARAJ 735 |

| 30211 | | Mitsubishi Canter |

| 30212 | | Mitsubishi Canter |

| 30214 | | ESCORT 335/345, HMT 2511 -3511 -ZETOR |

Exceptional Material and Durability

Fabricated from premium chrome steel, these taper roller bearings exhibit a polished finish and impressive hardness. This robust composition ensures long service life even under heavy loads, reducing maintenance requirements. Their durability and resistance to wear make them well-suited for both automotive and industrial environments.

Versatile Applications Across Industries

Designed to perform in various sectors such as automotive, heavy machinery, gearboxes, and axles, these bearings offer flexibility. Available in multiple bore sizes and rows, they can be integrated into a variety of mechanical assemblies, catering to specific demands for load and precision.

Precision Engineering and Compliance

Each bearing meets ISO standards and is offered with precision ratings up to P4, accommodating applications where accuracy is critical. Their meticulous manufacture guarantees smooth operation, low noise, and suitability for high-speed or high-load situations.

FAQs of Taper Roller Bearings:

Q: How does a taper roller bearing function in automotive and industrial machinery applications?

A: Taper roller bearings are designed to handle both radial and axial loads by utilizing tapered rollers, which efficiently distribute force. In automotive and industrial machinery, this allows them to support wheels, axles, and gearboxes, ensuring stable operation under varying load conditions and enhancing equipment longevity.Q: What makes these bearings suitable for high-load and precision applications?

A: These bearings are crafted from chrome steel with a high hardness (58-62 HRC) and offer high load capacity due to their tapered roller structure. With precision ratings of P0, P6, P5, or P4, they maintain accurate alignment and reliable performance, even under significant dynamic and static loads.Q: When should taper roller bearings be selected over other bearing types?

A: Taper roller bearings are ideal when both radial and axial load support is required, particularly in applications like automotive axles, gearboxes, and heavy machinery. They are preferred when enhanced durability, high load capacity, and precise performance are essential.Q: Where can these bearings be installed, and what are the typical dimensions available?

A: These bearings are suitable for installation in vehicles, industrial machines, gearboxes, and axles. They are available with bore sizes ranging from 24 mm to 380 mm and outside diameters from 52 mm to 540 mm, making them compatible with a wide variety of assemblies.Q: What is the typical process for installing taper roller bearings, and are they easy to mount?

A: The installation involves carefully aligning the bearing within the relevant housing and shaft, confirming proper lubrication, and securing the bearing as per standard guidelines. Their design ensures ease of installation, provided the correct tools and methods are used.Q: How does the design contribute to low noise and high durability?

A: The polished chrome steel construction, precision engineering, and steel cage ensure minimal friction, consistent operation, and reduced vibration. This leads to quiet performance and prolongs the bearings life, even in demanding or high-speed applications.Q: What are the primary benefits of using these taper roller bearings for exporters, importers, traders, and service providers?

A: These bearings offer high reliability, compliance with international ISO standards, and versatile application coverage. Their robust performance and availability in multiple sizes make them a dependable choice for exporters, importers, and service providers in India and globally.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Bearings Category

Delux Needle Bearing

Price 500 INR

Limiting Speed : 12000 RPM

Bearing Type : Needle Bearing

Inside Diameter : 25 mm

Lubrication Type : Grease

Seals Type : Open

Industrial Taper Roller Bearing

Limiting Speed : 5500 RPM

Bearing Type : Other, Industrial Taper Roller Bearing

Inside Diameter : 30 mm

Lubrication Type : Other, Grease or Oil

Seals Type : Open

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS